5 Critical Factors When Designing a Custom Rugged Tablet for OEM Applications

5 Critical Factors When Designing a Custom Rugged Tablet for OEM Applications

As an OEM, your brand is on the line. The custom rugged tablet you design is not just a product; it's the core of your customer's solution for fleet management, logistics, or public safety. Getting the design right from the start is paramount to performance, durability, and total cost of ownership.

While specs like MIL-STD-810G and IP67 are table stakes, true success lies in mastering the engineering nuances. Based on over a decade of experience as an ISO 9001:2015 certified manufacturer, we've identified the five most critical factors that determine the success of a custom rugged tablet project.

Factor 1: Thermal Management and Operating Temperature Range

The Challenge: Electronics generate heat, and confined, sealed rugged enclosures trap it. Overheating is a primary cause of premature component failure and performance throttling.

The Solution: A proactive thermal design is non-negotiable. This goes beyond specifying a standard temperature range (-20°C to 60°C). It involves:

Strategic Component Layout: Placing high-heat components like processors away from sensitive elements.

Use of Heat Spreaders and Thermal Interface Materials: To efficiently dissipate heat.

Real-World Validation: Testing the device not just in a chamber, but in its actual enclosure, under full computational load.

Ask Your OEM Partner: "How do you validate thermal performance under maximum load in the final housing design?"

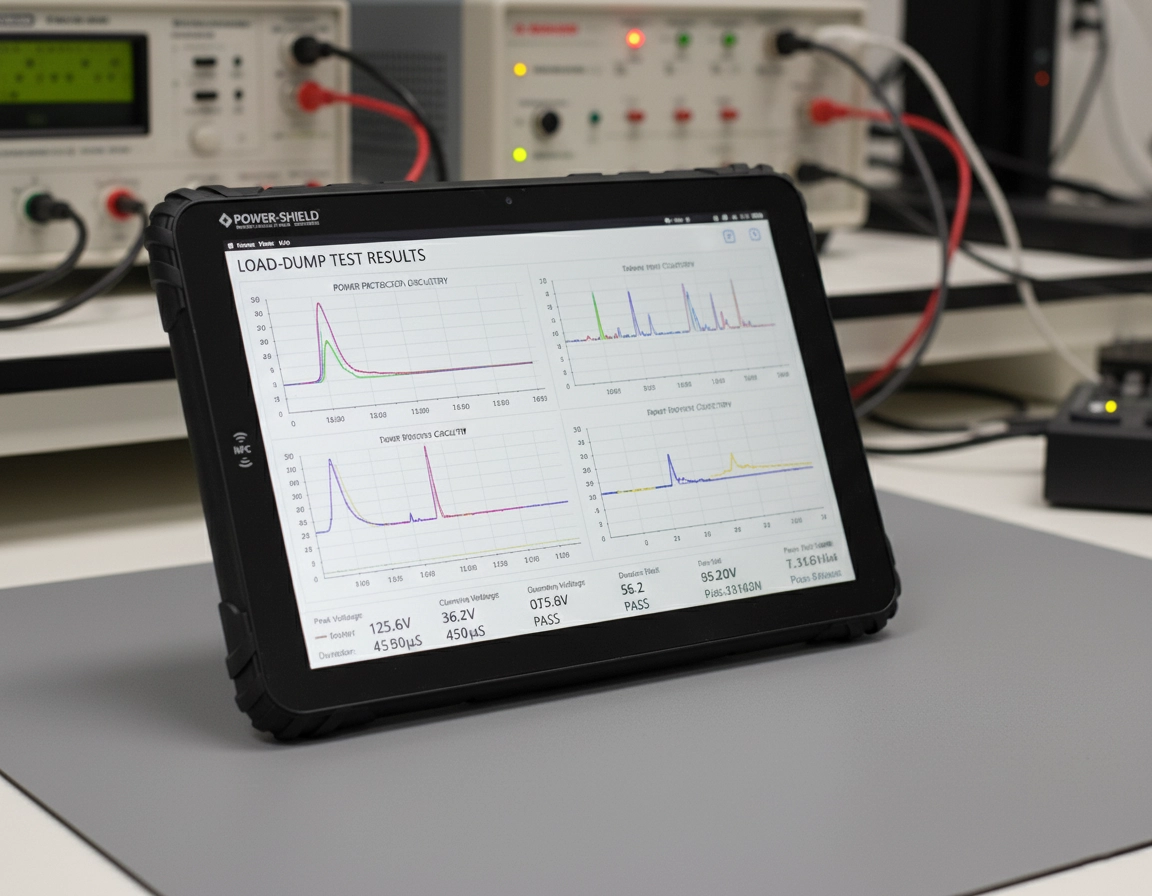

Factor 2: Power System Design and Vehicle Integration

The Challenge: The electrical environment in a vehicle is harsh, characterized by voltage spikes, load-dump events, and significant noise. A standard power circuit will fail.

The Solution: The power design must be automotive-grade. Key considerations include:

Wide Voltage Input: Supporting a range (e.g., 9-36 V DC) to handle fluctuations.

Ignition Sensing: For intelligent power-on/off sequences that prevent battery drain.

Transient Protection: Shielding the internal electronics from voltage spikes.

Stable Operation During Engine Cranking: When voltage can drop significantly.

Ask Your OEM Partner: "Can you provide the schematic for your power protection circuitry and test results for load-dump scenarios?"

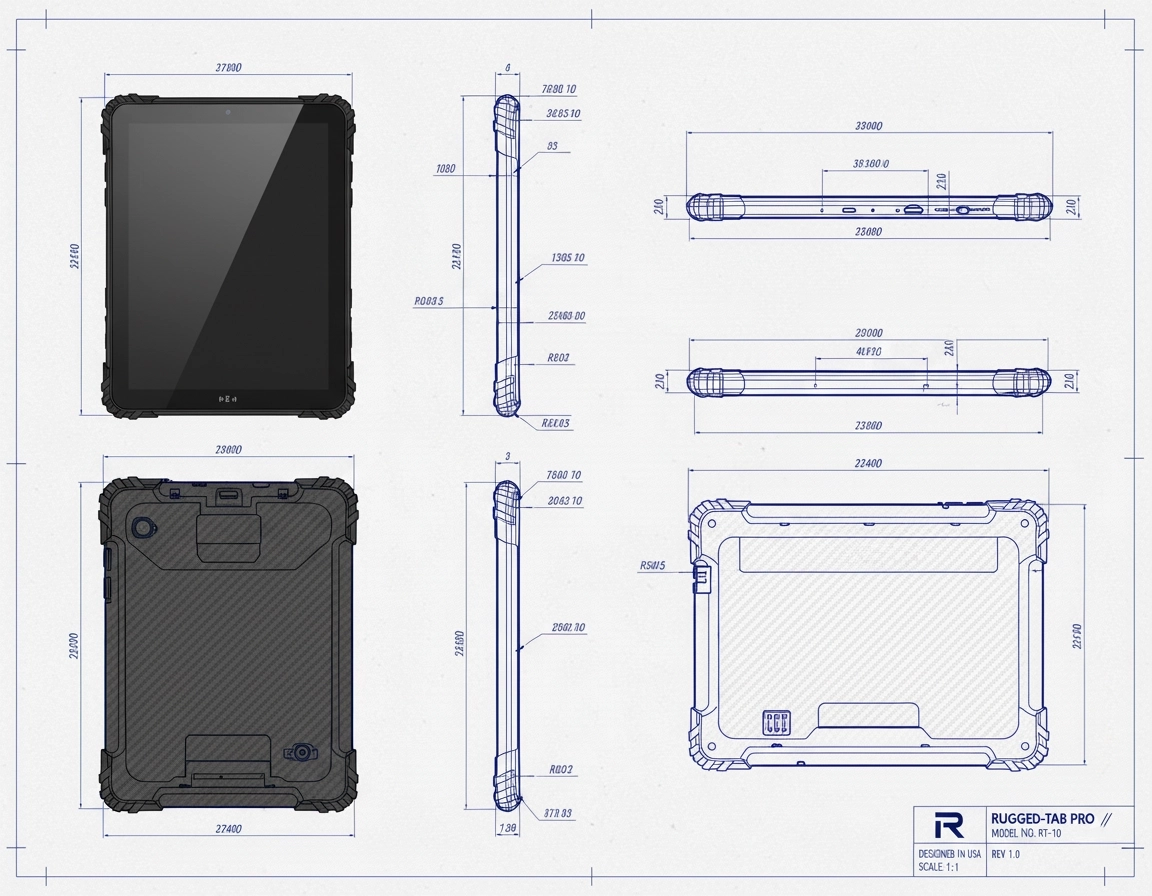

Factor 3: I/O Port Customization and Connector Durability

The Challenge: Off-the-shelf tablets rarely have the right mix of legacy and modern ports needed for specialized industrial applications. Standard USB-C ports are not durable enough for constant mating/de-mating.

The Solution: This is the heart of customization. Work with a partner who can:

Integrate Legacy Ports: Such as RS232 serial ports, DB9, or even CAN Bus for vehicle data.

Use Industrial-Grade Connectors: Like screw-down or locking M12-style connectors for USB, Ethernet, and power to ensure a secure connection in high-vibration environments.

Customize Port Placement: Position ports for easy access while protecting them from damage.

Ask Your OEM Partner: "What are our options for industrial locking connectors, and can you provide Mean Time Between Failures (MTBF) data for them?"

Factor 4: Display Readability and Touch Performance in All Conditions

The Challenge: An unreadable screen or an unresponsive touchscreen in bright sunlight or with gloves renders the entire device useless.

The Solution: Specify the display system with the end-user's environment in mind:

High-Brightness: A minimum of 1000 nits is essential for sunlight readability.

Optical Bonding: This process eliminates the air gap between the LCD and the cover glass, reducing glare and internal condensation.

Projected Capacitive (PCAP) Touch: With "glove touch" mode and the ability to reject rain and accidental contact.

Ask Your OEM Partner: "Is optical bonding a standard option, and what is the brightness and touch performance specification with gloves?"

Factor 5: The Certification and Compliance Strategy

The Challenge: Navigating the complex landscape of safety and wireless certifications (like FCC, CE, RED) can delay a product launch for months.

The Solution: Partner with a manufacturer that has a proven track record and in-house expertise in certification management. This includes:

Pre-Certified Core Platforms: Starting with a platform that already has key radio (FCC/CE) certifications can drastically reduce time-to-market.

In-House Pre-Compliance Testing: The ability to test and iterate on designs before submitting to an external lab.

Expert Guidance: A partner who can guide you on the specific certifications required for your target markets and applications.

Ask Your OEM Partner: "Which certifications do you hold in-house, and what is your process for managing the certification lifecycle for a custom project?"

Your Partner in Custom Rugged Tablet Design

At TOPICON HK, we don't just build to print; we partner with you to navigate these critical factors from concept to mass production. Our ISO 9001:2015 certified manufacturing process ensures that every custom rugged tablet we deliver meets the highest standards of quality, durability, and reliability.

Ready to design a rugged tablet that stands up to your most demanding applications?

Contact our engineering team today to discuss your OEM project requirements.