Emerging Trends in Vehicle-Mounted Mobile Data Terminals (2025 Edition)

Meta Description: Discover how 5G connectivity, AI-powered analytics, and modular designs are reshaping vehicle-mounted mobile data terminals for logistics, public safety, and construction fleets. Learn key selection criteria and implementation strategies.

Table of Contents

Introduction: The Connected Vehicle Revolution

The global market for vehicle-mounted mobile data terminals is projected to reach $12.8 billion by 2027, growing at a CAGR of 9.3%. This explosive growth underscores how MDTs are evolving from simple communication devices into intelligent command centers that drive operational efficiency across transportation and logistics sectors.

Market Context: Why MDTs Matter Now

According to recent industry analysis, fleets using advanced MDTs report 27% higher asset utilization and 31% reduction in fuel costs. Modern rugged Android terminals now serve as the central nervous system for connected vehicles, enabling real-time data exchange between drivers, dispatchers, and backend systems while withstanding harsh operational environments.

5 Key Technological Trends Shaping MDT Development

1. 5G Connectivity: Beyond Faster Download Speeds

While 5G delivers download speeds 10-100x faster than 4G LTE, its real value for MDTs lies in ultra-low latency (under 10ms) and network slicing capabilities. This enables:

Real-time HD video surveillance from multiple vehicle cameras

Instant over-the-air (OTA) updates for fleet-wide software management

Seamless handover between cellular networks during cross-border logistics operations

The TOPICON MDT880 5G Rugged Tablet demonstrates these capabilities with its integrated 5G modem supporting both Sub-6GHz and mmWave frequencies, ensuring reliable connectivity even in remote operational areas.

2. AI-Powered Fleet Intelligence: From Reactive to Predictive Operations

Modern MDTs leverage onboard AI processors to analyze data in real-time, enabling:

Driver behavior monitoring through analysis of acceleration, braking, and cornering patterns

Predictive maintenance alerts by correlating engine data with failure patterns

Dynamic route optimization that considers traffic, weather, and delivery windows simultaneously

Case studies from European logistics companies show AI-equipped MDTs reducing accident rates by up to 42% through proactive driver coaching.

3. Cloud-Based MDM: Centralized Control at Scale

Modern Mobile Device Management (MDM) platforms provide fleet operators with granular control over deployed MDTs, including:

Remote configuration and policy enforcement across thousands of devices

Real-time device health monitoring and proactive alerting

Geofenced application management that automatically adjusts functionality based on location

4. Multi-Camera Integration: 360° Situational Awareness

Advanced MDTs now support up to 4 simultaneous camera inputs through AHD, CVBS, or IP interfaces, enabling:

Blind spot elimination with real-time object detection

Incident documentation with automatically triggered recording

Driver authentication through integrated facial recognition

5. Modular Expansion: Tailoring to Specific Operational Needs

The trend toward modular MDT designs allows fleets to customize devices through:

Plug-and-play expansion modules for barcode scanning, RFID reading, or environmental sensing

Configurable I/O ports including RS-232/485, CAN Bus, and Ethernet interfaces

Hot-swappable peripheral connections that maintain operation during device changes

Industry-Specific Applications & Use Cases

Logistics & Transportation

Last-mile delivery companies use MDTs with integrated barcode scanners and signature capture to reduce package handling time by 35%. Real-time route optimization has demonstrated 22% reduction in fuel consumption across fleets of 100+ vehicles.

Public Safety & Emergency Services

Police and fire departments leverage MDTs with priority 5G network access and secure video streaming capabilities. Integrated gunshot detection and automatic license plate reading have improved response times by 28% in urban deployments.

Construction & Mining

Heavy equipment monitoring through CAN Bus integration enables predictive maintenance, reducing unplanned downtime by 45%. Off-road navigation systems with terrain awareness have decreased fuel consumption by 18% in mining operations.

Cold Chain Logistics

MDTs with integrated temperature monitoring and LoRa connectivity maintain cargo integrity throughout transit. Automated compliance reporting has reduced administrative overhead by 60% for pharmaceutical transporters.

MDT Selection Criteria: 7 Key Evaluation Factors

Environmental Durability - IP67 rating or higher for dust/water resistance and MIL-STD-810H certification for shock/vibration

Display Readability - Minimum 1000 nits brightness with anti-glare coating for sunlight visibility

Thermal Performance - Operational temperature range of -30°C to 70°C for global deployment

Connectivity Options - 5G, Wi-Fi 6E, Bluetooth 5.2, and GNSS with dual-band positioning

Expansion Capabilities - Modular I/O including RS-232/485, CAN Bus, Ethernet, and USB-C

Power Management - Wide voltage input (9-36V DC) with ignition sensing and surge protection

Security Features - Hardware-level encryption, secure boot, and remote wipe capabilities

Implementation Challenges & Solutions

Challenge 1: System Integration Complexity

Solution: Choose MDTs with open API frameworks and pre-built connectors for major telematics platforms. TOPICON devices, for instance, offer SDKs for seamless integration with leading fleet management software.

Challenge 2: Total Cost of Ownership

Solution: Implement modular MDTs that can be upgraded rather than replaced. TOPICON's cradle-based design allows for core tablet upgrades while reusing existing mounts and peripherals, reducing refresh costs by 40%.

Challenge 3: User Adoption & Training

Solution: Deploy devices with intuitive Android interfaces and provide role-based training programs. Fleets that implement comprehensive change management report 67% higher user satisfaction scores.

TOPICON's Next-Generation MDT Solutions

TOPICON's vehicle-mounted MDT portfolio addresses these evolving industry requirements through:

MDT880 5G Rugged Tablet

8-inch 1000nit sunlight-readable display

Integrated 5G (Sub-6GHz and mmWave) and Wi-Fi 6E connectivity

IP67 rating and MIL-STD-810H compliance

Modular expansion via smart cradle (RS-232, RJ45, USB 3.0)

Advanced AI processing for real-time analytics

MDT865 Industrial Rugged Tablet

Cost-optimized solution for budget-conscious deployments

4G LTE connectivity with fallback to 3G/2G networks

Wide voltage input (9-36V DC) with ignition sensing

Compatible with TOPICON's vehicle mount ecosystem

These solutions have been deployed across 15,000+ vehicles globally, demonstrating 99.7% operational uptime in demanding environments from Arctic logistics to Middle Eastern construction sites.

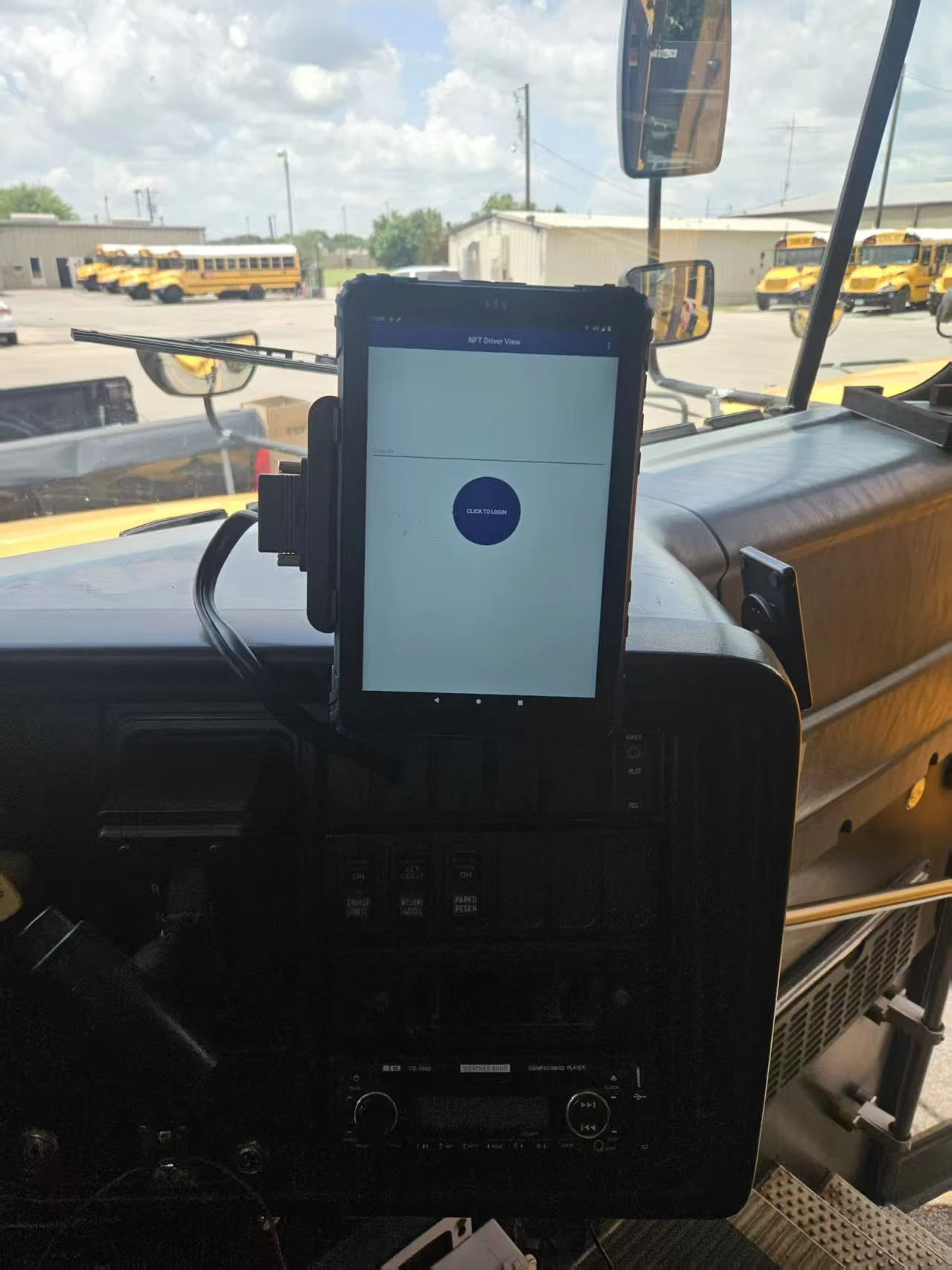

The versatile mobile data terminal for streamlined fleet operations and driver workflow

The MDT765 is a proven, popular rugged tablet designed to bring mission-critical digital workflows directly to the cab.

It serves as the central hub for drivers and fleet managers, enabling everything from navigation and e-logging to

advanced safety camera systems and remote device management.

Core Features & Specifications:

7-inch Rugged Display: Optimized for clarity and usability in various lighting conditions.

Versatile Connectivity: 2G/3G/4G mobile network module ensures constant communication.

Advanced Fleet Telematics Integration: Connects seamlessly to vehicle data

(e.g., fuel consumption, diagnostics) via a dedicated cradle with RS232 interface.

Expandable Safety & Workflow Ecosystem: Features an NFC card reader and supports an optional camera system.

When combined with the TOPICON camera hub, it can support up to four 1080p AHD cameras for real-time safety views.

Proven Global Deployment & Management:

This solution is trusted by fleets to digitize and streamline operations.

It extends the enterprise workflow to mobile assets with robust management tools, including support for

MDM remote control, OTA upgrades, and custom firmware/APK integration, ensuring high uptime and adaptability.

Future Outlook: What's Next for Vehicle MDTs

The next evolution of vehicle-mounted MDTs will focus on three key areas:

Edge Computing Integration

Future MDTs will incorporate more powerful edge processors capable of running complex AI models locally, reducing latency and bandwidth requirements for video analytics and sensor processing.

Enhanced Cybersecurity

With the increasing connectivity of fleet vehicles, hardware-level security modules and blockchain-based verification will become standard features to prevent unauthorized access and data manipulation.

Sustainability Features

Next-generation MDTs will include energy monitoring capabilities and optimize power consumption based on usage patterns, contributing to broader corporate sustainability initiatives.

Frequently Asked Questions

What is the typical lifespan of a vehicle-mounted MDT?

Industrial-grade MDTs from reputable manufacturers typically have a service life of 5-7 years, with extended availability of replacement parts and ongoing software support.

How do MDTs differ from consumer tablets in vehicle applications?

MDTs feature ruggedized construction (IP67, MIL-STD-810H), wide operating temperature ranges (-30°C to 70°C), vehicle-specific I/O (CAN Bus, ignition sensing), and professional MDM support—all critical for reliable 24/7 operation.

Can existing fleet vehicles be retrofitted with modern MDTs?

Yes, most modern MDTs are designed for straightforward retrofitting with standardized mounting systems and vehicle-specific power adapters. TOPICON offers custom installation kits for various vehicle types.

What ROI can fleets expect from MDT implementation?

Typical ROI timeframes range from 8-18 months, achieved through reduced fuel consumption (15-25%), lower administrative costs (30-40%), decreased vehicle downtime (20-35%), and improved asset utilization (25-35%).

Conclusion: Building Your Connected Fleet Strategy

Vehicle-mounted mobile data terminals have evolved from simple communication tools to intelligent platforms that drive operational excellence. By understanding the key trends—5G connectivity, AI analytics, and modular design—fleet operators can make informed decisions that deliver measurable business value.

As vehicles become increasingly connected, the strategic selection and implementation of MDTs will play a crucial role in determining competitive advantage across transportation, logistics, and mobile workforce sectors.

Author Bio: This article was contributed by TOPICON's Automotive Solutions team, drawing on decades of combined experience in designing and deploying rugged computing solutions for global fleet operations.

Learn more in our mobile data terminal solution page.