RFID Tablet Applications: How Rugged RFID Tablets Are Used Across Industries

Figure 1: Rugged RFID tablets streamline operations across diverse industrial environments through automated identification

Figure 1: Rugged RFID tablets streamline operations across diverse industrial environments through automated identificationIn today's data-driven industrial landscape, the convergence of mobility and automatic identification has created powerful operational tools. Among these, the RFID tablet has emerged as a transformative device, combining the processing power and display capabilities of a tablet with the hands-free scanning ability of RFID technology. This comprehensive guide explores the diverse RFID tablet applications and real-world rugged RFID tablet use cases that are revolutionizing efficiency and accuracy across multiple sectors.

What Is an RFID Tablet?

An RFID tablet is an integrated mobile computing device that combines a rugged tablet computer with an embedded UHF or HF RFID reader. This enables users to automatically identify, track, and manage tagged items without direct line-of-sight scanning, while simultaneously accessing databases, updating records, and completing workflows on a single device.

RFID Tablet vs Handheld RFID Reader

Integrated Display: RFID tablets provide full data visualization and form entry, unlike standalone readers that require separate devices for data viewing

Processing Power: Tablets run full operating systems and applications, while readers typically have limited computing capabilities

All-in-One Solution: Eliminates the need to carry multiple devices (reader + PDA/phone + printer)

Why Choose a Rugged RFID Tablet?

Durability First: Engineered to withstand industrial drops, vibrations, temperature extremes, and exposure to dust/water

Continuous Operation: Built for shift-long use with hot-swappable batteries and vehicle docking options

Enterprise Ready: Designed to integrate with existing business systems and withstand rigorous daily use

Why Use RFID Tablets in Industrial Environments?

The industrial adoption of rugged RFID tablets is driven by specific environmental challenges and operational requirements that standard consumer devices cannot meet.

Harsh Environmental Resistance

Industrial settings expose devices to dust, moisture, extreme temperatures, and constant vibration. Rugged RFID tablets with IP65/67 ratings and MIL-STD-810H certification ensure reliable operation where consumer devices would fail.

Mobile Workforce Enablement

Real-time data capture and updates are critical for mobile teams. RFID tablets provide immediate inventory visibility, task verification, and status updates without returning to stationary workstations.

Enterprise System Integration

Seamless connectivity with Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP), and fleet management platforms ensures data consistency and eliminates manual re-entry errors.

RFID Tablet Applications by Industry

The versatility of RFID tablet applications extends across numerous sectors, each with unique operational challenges that RFID technology helps solve.

Warehouse & Logistics

Inventory Counting: Rapid bulk scanning of entire pallets or shelves without unpacking, reducing counting time by up to 90% compared to manual methods.

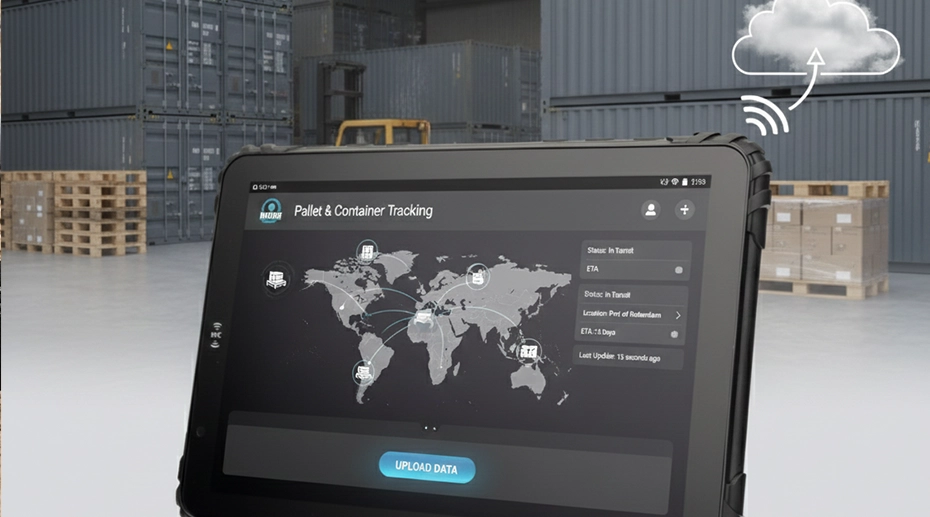

Pallet & Container Tracking: Real-time visibility of asset movement throughout the supply chain, from receiving to shipping docks.

Inbound / Outbound Verification: Automatic matching of received shipments against purchase orders and outbound loads against shipping manifests.

Manufacturing & Asset Management

Tool & Equipment Tracking: Locate specialized tools, calibration equipment, and safety gear across large facilities, reducing search time and loss.

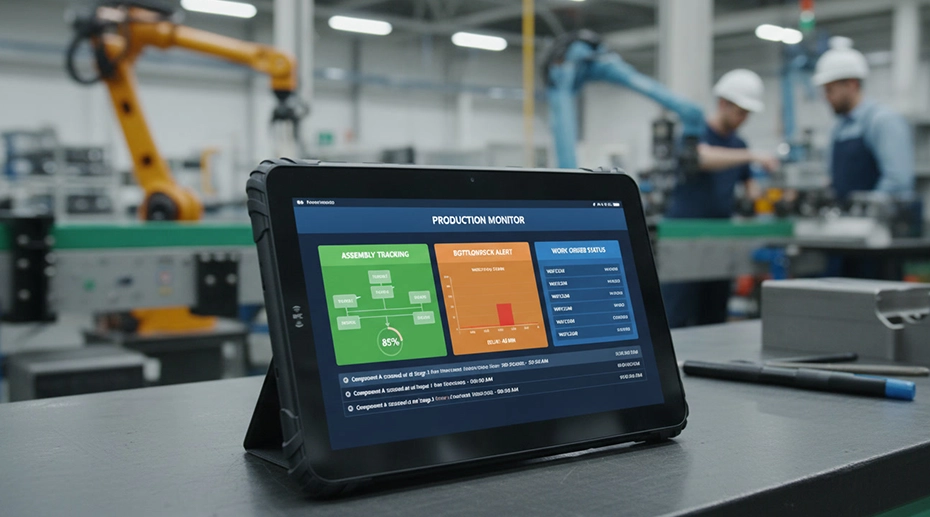

Work-in-Progress Visibility: Track components through assembly stages, monitor production bottlenecks, and maintain accurate work order status.

Work-in-Progress Visibility: Track components through assembly stages, monitor production bottlenecks, and maintain accurate work order status.

Retail & Smart Store Operations

Fast Inventory Audits: Complete store-wide inventory counts in hours instead of days, with accuracy rates exceeding 99.5%.

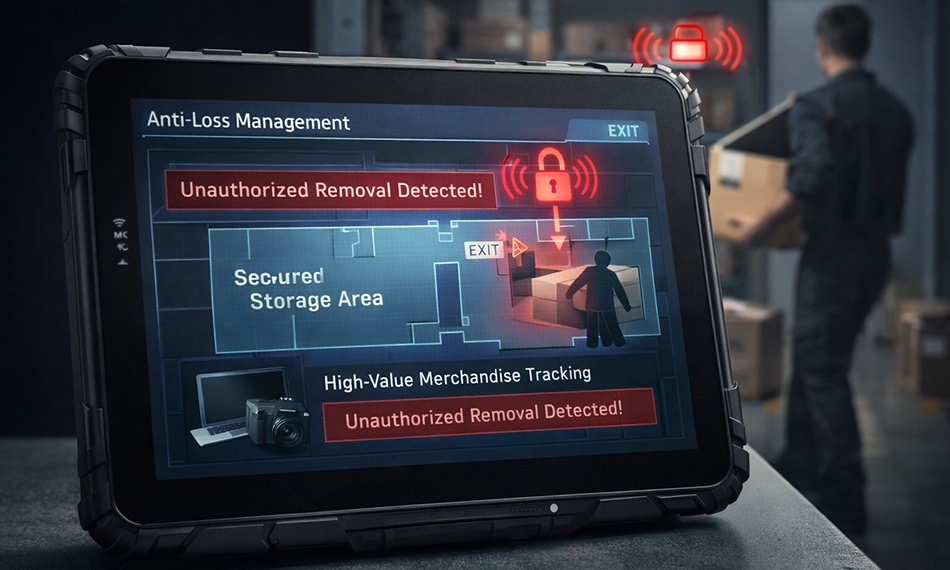

Anti-Loss Management: Monitor high-value merchandise movement and receive alerts for unauthorized item removal from secured areas.

Transportation & Fleet Management

Cargo Identification: Verify loaded containers and pallets against shipping manifests without opening trailers or breaking seals.

Vehicle-Mounted RFID Tablet Use Cases: In-cab devices for drivers to verify pickups/deliveries, complete electronic proof of delivery, and manage route assignments with integrated RFID verification.

Public Safety & Government

Evidence Tracking: Maintain chain of custody for forensic items with automated logging of check-in/check-out events and storage location updates.

Patrol Equipment Management: Ensure officers have required gear checked out, track maintenance schedules for weapons and body armor, and automate inventory audits.

Key Benefits of Rugged RFID Tablets

All-in-One Device

Consolidates multiple tools (scanner, computer, camera, communication device) into a single rugged unit, reducing equipment costs and training complexity.

Improved Efficiency

Enables workers to complete tasks 3-5 times faster than manual methods, with simultaneous scanning and data entry capabilities.

Reduced Human Error

Automated data capture eliminates manual entry mistakes, ensuring inventory accuracy rates consistently above 99%.

Long Lifecycle & Lower TCO

Rugged construction and enterprise-grade components deliver 5+ years of service life, significantly reducing total cost of ownership versus consumer devices.

Conclusion: Choosing the Right RFID Tablet for Your Industry

The selection of an appropriate rugged RFID tablet depends on multiple factors unique to each operational environment. Key considerations include read range requirements (UHF for long-range vs. HF for short-range), environmental protection levels (IP rating for dust/water resistance), battery life needs (shift-long vs. intermittent use), and integration capabilities with existing enterprise systems.

For warehouse operations prioritizing bulk scanning at dock doors, a vehicle-mounted UHF RFID tablet with extended read range may be ideal. In manufacturing settings where tools and components are handled closely, an HF RFID tablet with precise item-level tracking might be more appropriate. Retail environments may benefit from a balance of RFID and barcode capabilities for mixed inventory management.

Regardless of industry, the common thread is the need for reliability, accuracy, and seamless data integration. As RFID technology continues to advance and become more accessible, its integration with rugged mobile computing platforms creates opportunities for operational transformation across virtually every sector that manages physical assets.

Next Steps: To explore specific implementation scenarios or technical specifications for your industry's needs, review our detailed RFID tablet solution guide or contact us to discuss rugged RFID tablet options tailored to your operational requirements.