RFID Tablet Solution for Industrial Data Capture and Asset Tracking

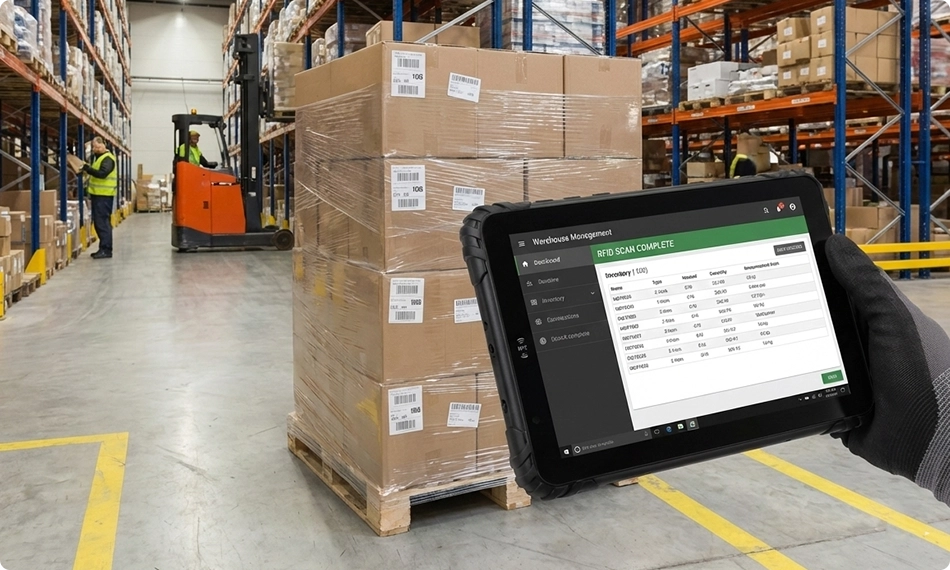

Deploy rugged RFID-enabled tablets to optimize inventory tracking, warehouse operations, and logistics management.

What Is an RFID Tablet?

RFID tablets are rugged Android devices equipped with RFID scanning capabilities, designed as all-in-one industrial data capture terminals to capture, read, and process data from RFID tags in real-time. These tablets combine mobility, durability, and advanced connectivity, making them ideal for warehouse, logistics, and industrial environments.They are widely used as part of an RFID tablet solution integrating hardware, software, and backend systems.

Key Benefits of RFID Tablets

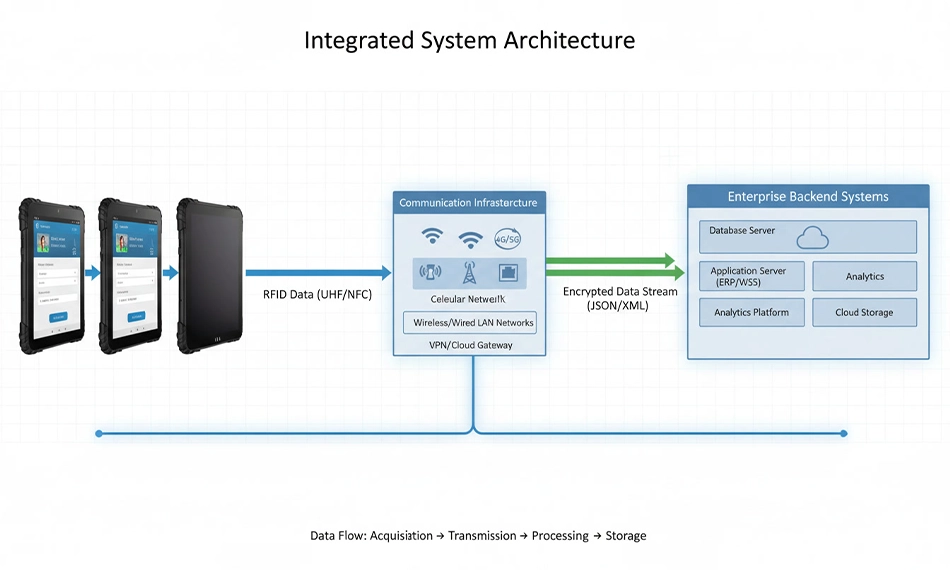

System Architecture and Software Integration

The true value of an RFID tablet solution lies in its ability to integrate seamlessly into existing enterprise ecosystems.

TOPICON RFID tablets are designed as integration-ready hardware platforms, enabling smooth data exchange between field operations and customer-managed backend systems, where RFID scan data can be transformed into actionable business intelligence.

Enterprise System Integration

TOPICON RFID tablets are designed to support integration with Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP), and fleet management platforms.

Through standardized communication interfaces, RFID data captured at the device level can be transmitted to customer or third-party systems for inventory updates, procurement workflows, asset tracking, and logistics coordination across the supply chain.

Development Framework Support

API and SDK support enables system integrators and software developers to build custom applications on TOPICON RFID tablet hardware.Comprehensive software development kits provide access to RFID reader controls, device management functions, and data processing capabilities, allowing in-house or third-party developers to create bespoke applications that perfectly match unique operational requirements.

Cloud-Based Data Synchronization

RFID tablets are designed to work with cloud-based backend systems for real-time or near-real-time data synchronization.

Depending on the customer's system architecture, data captured in the field can be buffered locally during offline operation and synchronized with cloud platforms when connectivity is restored, ensuring data continuity and operational visibility.

Secure Communication Infrastructure

Secure communication over 4G/5G and Wi-Fi is supported to protect data during transmission between RFID tablets and backend systems.

Industry-standard encryption, certificate-based authentication, and VPN compatibility allow customers to implement secure data transfer policies aligned with their enterprise IT security frameworks.

Architecture Components Overview

The following architecture illustrates a typical integration model based on customer or third-party systems.

Edge Layer: RFID tablets with local data processing and storage capabilities

Communication Layer: Multi-network connectivity with automatic failover between 4G/5G, Wi-Fi, and satellite

Integration Layer: RESTful APIs, web services, and middleware for enterprise system connectivity

Application Layer: Custom business logic, workflow automation, and user interface components

Security Layer: End-to-end encryption, device authentication, and access control management

Management Layer: Remote device administration, software updates, and performance monitoring

Implementation Considerations

Scalability: Architecture must support deployment from single units to fleets of thousands of devices

Interoperability: Compatibility with legacy systems while enabling migration to modern platforms

Data Governance: Clear policies for data ownership, retention, and compliance with industry regulations

Performance Optimization: Balancing real-time data requirements with network bandwidth constraints

Disaster Recovery: Redundant systems and data backup strategies for business continuity

Implementation strategies and software architectures may vary depending on customer requirements and system providers. TOPICON focuses on delivering robust RFID tablet hardware and integration-ready platforms.

RFID Tablet Deployment Scenarios Across Industries

The versatility of rugged RFID tablets extends across the entire industrial landscape, transforming traditional workflows into automated, data-driven processes. Each sector presents unique challenges that are addressed through specialized deployment scenarios, from warehouse inventory management to mobile field operations.

Warehouse & Inventory Management

Automated Stock Counting

Automated Stock Counting

RFID tablets enable rapid bulk scanning of entire pallets or shelves without unpacking, reducing cycle count time by up to 90% compared to manual methods while achieving accuracy rates above 99.5%.

Receiving & Shipping Verification

Receiving & Shipping Verification

Instant verification of inbound shipments against purchase orders and outbound loads against shipping manifests, automatically updating inventory records in real-time as goods move through dock doors.

Multi-Location Asset Tracking

Multi-Location Asset Tracking

Continuous visibility of tools, equipment, and materials across multiple storage zones, maintenance areas, and production cells within large-scale warehouse facilities.

Integrated Workflow Systems

Integrated Workflow Systems

Seamless integration with warehouse management systems (WMS), automated guided vehicles (AGVs), and picking carts to create optimized, paperless workflows from receiving to shipping.

Logistics & Distribution Centers

Cross-Dock Operations

Cross-Dock Operations

Real-time identification and sorting of tagged parcels and pallets during fast-paced cross-docking, reducing handling time and minimizing misroutes in high-volume distribution hubs.

Container & Pallet Management

Container & Pallet Management

Tracking returnable transport items (RTIs), shipping containers, and reusable pallets throughout complex supply chains, automating check-in/check-out processes and loss prevention.

Last-Mile Delivery Verification

Last-Mile Delivery Verification

Driver-operated RFID tablets for verifying parcel deliveries against manifests, capturing electronic proof of delivery, and updating shipment status without manual data entry.

Temperature-Sensitive Logistics

Temperature-Sensitive Logistics

Monitoring and verifying temperature-controlled shipments in pharmaceutical and food distribution, with RFID tablets operating reliably in refrigerated environments and cold chain facilities.

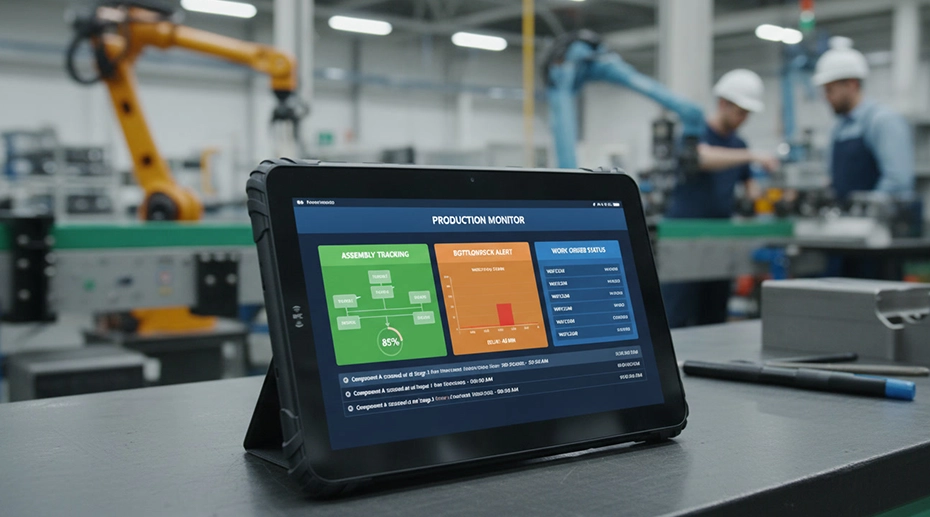

Manufacturing & Asset Tracking

Work-in-Progress Tracking

Work-in-Progress Tracking

Real-time visibility of components and assemblies as they move through production stages, automatically updating manufacturing execution systems (MES) without stopping the line.

Tool & Equipment Management

Tool & Equipment Management

Automated check-in/check-out of calibrated tools, specialized fixtures, and safety equipment across maintenance departments and production floors, reducing loss and downtime.

Quality Control & Traceability

Quality Control & Traceability

Linking RFID-tagged products with quality inspection records, test results, and component origins to maintain complete traceability from raw materials to finished goods.

Maintenance & Calibration Scheduling

Maintenance & Calibration Scheduling

Automated alerts for scheduled maintenance, calibration due dates, and equipment service histories based on RFID scans of machinery and test equipment tags.

Vehicle-Mounted & Mobile Operations

Forklift-Mounted Inventory Control

Forklift-Mounted Inventory Control

Dock-mounted RFID tablets on forklifts for real-time put-away and picking verification, automatically updating storage locations as loads are moved without manual scanning.

Field Service & Maintenance

Field Service & Maintenance

Mobile technicians using vehicle-mounted tablets to identify tagged equipment at customer sites, access service histories, and log repair activities directly into enterprise systems.

Public Safety & Emergency Response

Public Safety & Emergency Response

Police, fire, and EMS vehicles equipped with rugged tablets for tracking tagged equipment, managing evidence chains of custody, and accessing critical asset locations during emergencies.

Transportation Fleet Management

Transportation Fleet Management

In-cab RFID tablets for commercial drivers to verify loaded cargo against manifests, complete electronic logging, and manage route assignments with integrated asset verification.

RFID Tablet Deployment Scenarios

Topicon RFID tablets are deployed across warehouses, distribution centers, and logistics operations. They ensure accurate data capture while withstanding daily operational challenges such as dust, vibration, and accidental drops.

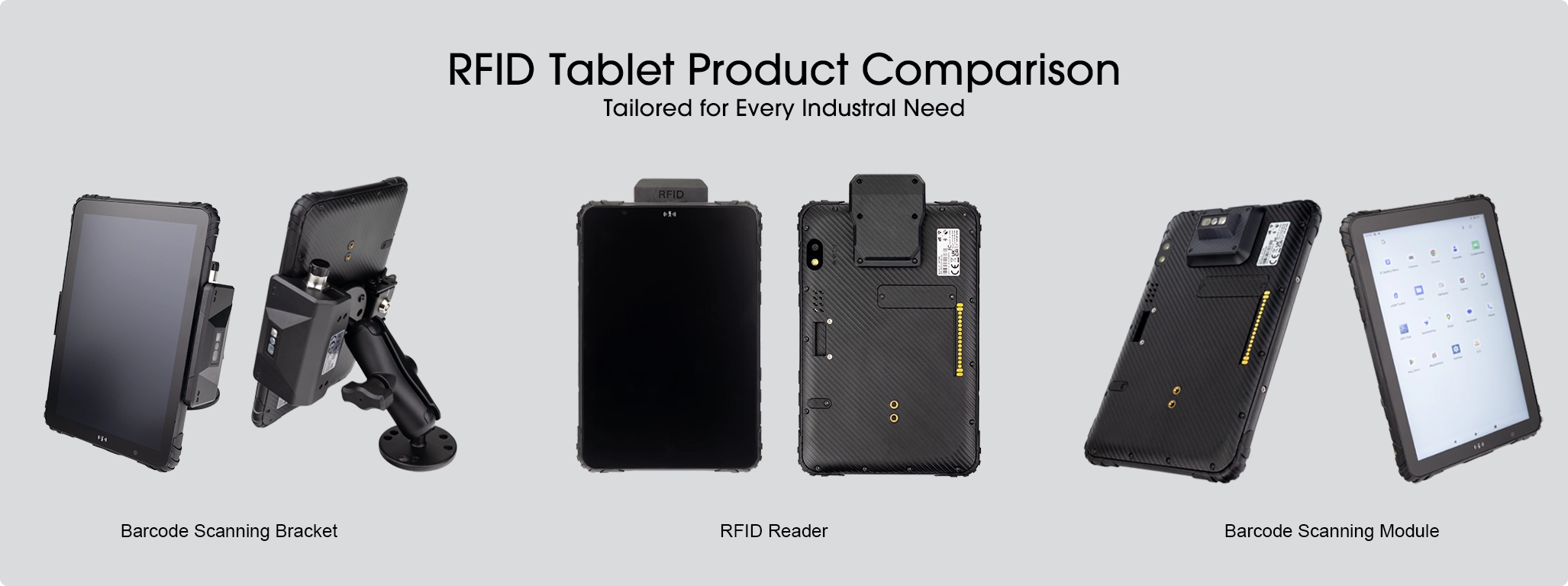

RFID Tablet Solution Components

Our RFID tablet solutions include:

Rugged Android tablet base unit

Optional RFID scanning module

Optional barcode scanning module

Docking stations and battery-backed brackets

Compatibility with WMS, ERP, and custom warehouse software

How to Choose the Right RFID Tablet Solution

Consider the following factors when selecting an RFID tablet for your operation:

Scanning Capabilities

Required scanning capabilities (RFID only vs. RFID + barcode)

Environmental Ruggedness

Environmental ruggedness (IP rating, drop resistance)

Screen Visibility

Screen size and sunlight readability for warehouse lighting

Battery Requirements

Battery life and swappable battery support

System Integration

Integration with existing warehouse software and workflow

Recommended Rugged RFID Tablet Models for Industrial Solutions

These models are designed to support scalable RFID tablet solutions across different deployment scenarios.

MDT865 RFID Rugged Tablet

8-inch Android tablet with optional RFID & barcode scanning modules. IP67, MIL-STD-810G rugged design. Supports docking and bracket solutions.

View Product

MDT880 RFID Tablet

8-inch sunlight-readable display, 1000 nits. Optional RFID & barcode scanning. IP67 rugged and compatible with docking solutions for warehouse deployment.

View Product MDT1065 RFID Rugged Tablet

MDT1065 RFID Rugged Tablet

10.1-inch Android tablet with IP67 protection, swappable battery. Supports optional RFID module and docking solutions for heavy warehouse use.

View Product MDT665 Rugged RFID Handheld

MDT665 Rugged RFID Handheld

5.72-inch rugged Android handheld terminal. supporting barcode scanning, cradles, and secure mounts. Features IP68 waterproof rating, and optional RFID module.

View ProductGet Your Complete RFID Tablet Solution Today

Contact Topicon to explore rugged RFID tablet options for your warehouse and inventory management needs.

Request a ConsultationFAQ

What is an RFID tablet used for?

RFID tablets are used to scan, read, and process RFID tags in warehouses, logistics centers, and industrial environments for inventory tracking and asset management.

Can RFID tablets also scan barcodes?

Yes, optional barcode scanning modules are available for combined RFID + barcode operations.

Are RFID tablets durable enough for warehouse use?

Topicon RFID tablets are rugged, meeting IP67 and MIL-STD-810G standards, designed to withstand dust, water, and drops.

This RFID tablet solution is widely deployed in warehouse environments, including distribution centers, fulfillment hubs, and cold storage facilities.