Industrial Tablet Explained: Design, Certifications, and Real-World Applications

Article Navigation

What Is an Industrial Tablet?

An industrial tablet is a purpose-built mobile computing device engineered for reliable operation in demanding industrial environments, designed for long-term deployment rather than consumer use.

Core Definition:

Industrial tablets are computing platforms optimized for vehicle-mounted and fixed installations with emphasis on environmental tolerance, system stability, and long lifecycle availability—typically 5-7 years versus 1-2 years for consumer devices.

Unlike consumer tablets that prioritize aesthetics and portability, industrial tablets focus on reliability, connectivity, and integration capabilities for mission-critical operations.

Related Solutions: Explore rugged tablets for harsh environments or our dedicated industrial tablet sub hub for specific application guidance.

Industrial Tablet vs Consumer Tablet: Key Differences

Learn more: Rugged Android Tablet solutions or explore Mobile Data Terminal capabilities.

Key Design Characteristics of Industrial Tablets

Rugged Housing & Mechanical Protection

The design philosophy prioritizes protection over aesthetics, with reinforced corners, raised bezels, and internal shock isolation to withstand repeated impacts and vibrations in industrial settings.

Industrial-Grade Display & Touch

Displays emphasize readability over resolution—high brightness (800-1000+ nits), anti-reflective coatings, and glove/wet touch capability take precedence over pixel density in industrial environments.

Extended I/O & Expansion

Industrial connectivity extends beyond USB to include legacy serial ports (RS232/485), control interfaces (GPIO), vehicle data buses (CAN), and proprietary docking systems for specialized peripherals.

Power Design for Continuous Operation

Power systems are engineered for 24/7 operation with vehicle ignition sensing, hot-swappable batteries, and intelligent charging circuits that prevent battery degradation during continuous use.

Industrial Certifications & Standards Explained

IP Ratings (IP65 / IP67 / IP68)

Ingress Protection ratings define environmental sealing against dust and water:

IP65: Dust-tight and protected against water jets from any direction

IP67: Dust-tight and protected against temporary immersion (up to 1m for 30 minutes)

IP68: Dust-tight and protected against continuous immersion under specified conditions

For applications requiring water resistance, explore waterproof rugged tablet solutions.

MIL-STD-810

U.S. military standard testing for environmental engineering, including:

Drop resistance from 4-6 feet onto concrete

Shock and vibration tolerance equivalent to vehicle/machinery environments

Temperature shock and altitude testing

Humidity and fungus resistance

Operating Temperature & Vibration Resistance

Industrial tablets typically operate from -20°C to 60°C (-4°F to 140°F), with specialized units reaching -30°C to 70°C. Vibration resistance is tested according to ISO 16750-3 or MIL-STD-810G Method 514 for continuous vehicle operation.

Related: Comprehensive overview in our Rugged Tablet page.

Operating Systems Used in Industrial Tablets

Why Android Is Widely Used in Industrial Tablets

Android has become the dominant OS in industrial tablets due to:

Open ecosystem enabling hardware and software customization

Long-term support versions (Android Enterprise Recommended)

Lower total cost of ownership compared to Windows licensing

Familiarity among developers and IT teams

Robust MDM and enterprise security features

Android vs Windows in Industrial Environments

While Windows remains in specialized applications, Android dominates mobile industrial computing:

Android advantages: Touch-first interface, power efficiency, app ecosystem, cost-effective hardware

Windows advantages: Legacy enterprise software compatibility, x86 architecture support, specialized industrial applications

For Android-focused solutions, explore our Rugged Android Tablet .

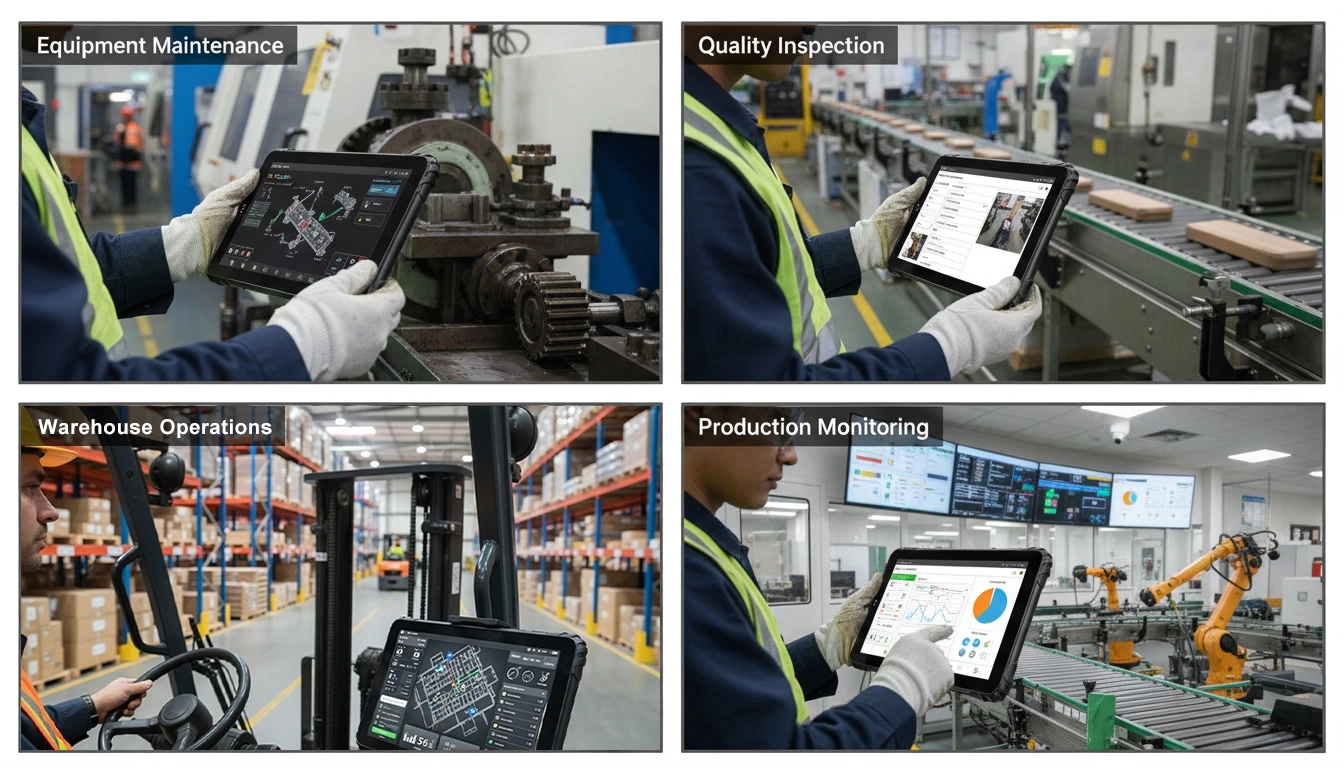

Common Applications of Industrial Tablets

Transportation & Fleet Operations

ELD compliance, route optimization, vehicle diagnostics

Explore Solutions →Construction & Heavy Equipment

Equipment monitoring, site management, field documentation

Explore Solutions →Public Safety & Field Services

Emergency response, utility maintenance, inspection reporting

Explore Solutions →Industrial Tablet vs Mobile Data Terminal (MDT)

While both serve mobile computing needs in industrial environments, understanding their boundaries is crucial:

Definition Boundary

Industrial Tablets: General-purpose computing devices adapted for harsh environments with full OS capabilities.

MDTs: Specialized terminals focused on specific applications like dispatch, messaging, and form-based data entry.

Use Case Evolution

The line between tablets and MDTs is blurring as modern industrial tablets incorporate traditional MDT functions while offering greater flexibility and application support.

For specialized terminal applications, explore our Mobile Data Terminal or read our MDT explained article.

How to Choose an Industrial Tablet for Your Application

Environment & Installation Type

Evaluate temperature extremes, moisture/dust exposure, vibration levels, and mounting requirements (vehicle, forklift, handheld).

Performance & Connectivity Requirements

Determine necessary processing power, display visibility needs, wireless connectivity (LTE, Wi-Fi, GNSS), and peripheral interfaces (serial, GPIO, docking).

Lifecycle & OEM Support

Consider product availability duration, OS support lifecycle, customization options, and manufacturer support for integration and long-term maintenance.

Industrial Tablet Trends: What's Next?

Android Dominance: Continued growth of Android as the primary OS for industrial mobility, with extended enterprise features and security enhancements.

Vehicle-Centric Design: Tablets specifically engineered for vehicle integration with CAN bus support, ignition sensing, and automotive-grade components.

Advanced MDM & Remote Management: Cloud-based device management, predictive maintenance, and over-the-air configuration for large-scale deployments.

Edge AI Integration: On-device machine learning for real-time analytics, object recognition, and predictive maintenance in field applications.

Learn more: MDM for rugged device management or explore future-ready rugged Android tablet solutions.

Conclusion: When an Industrial Tablet Makes Sense

Industrial tablets are purpose-built computing platforms designed for long-term, mission-critical deployment in demanding environments — not consumer devices with rugged cases.

When your application requires reliable operation in challenging conditions, extended lifecycle support, enterprise-grade management, and professional integration capabilities, an industrial tablet represents the appropriate technological investment rather than a compromise between consumer convenience and industrial requirements.