Why Manufacturing Environments Require Rugged Tablets (Not Consumer Devices)

Industry Insight | Manufacturing Technology | Equipment Selection Guide

Understanding why standard consumer tablets fail in industrial settings and what makes rugged tablets essential

While consumer tablets work well in offices and homes, manufacturing environments present unique challenges that demand specialized rugged tablets designed specifically for industrial use. This guide explains the critical differences and why the right hardware choice impacts productivity, data integrity, and total cost of ownership.

Quick Navigation

What Makes Manufacturing Environments Harsh for Mobile Devices

Manufacturing facilities present challenges that consumer electronics aren't designed to withstand. Understanding these environmental factors is crucial for selecting the right mobile computing solution.

Physical Impacts & Vibration

Regular drops from workbenches (3-5 feet)

Constant vibration from machinery

Accidental impacts from tools or parts

Heavy objects placed on devices

Temperature Extremes

Foundries: 40-50°C+ (104-122°F+)

Cold storage: -20°C to 0°C (-4°F to 32°F)

Outdoor receiving areas

Rapid temperature changes

Contaminants & Liquids

Metal dust in machining areas

Oil, coolant, and lubricant exposure

Chemical splashes in processing

Water in cleaning areas

Operational Demands

24/7 shift operations

Glove-wearing operators

High ambient noise levels

Low-light conditions

Real-World Example:

An automotive parts manufacturer reported consumer tablet failures within 2-3 months in their machining department. Metal shavings entered charging ports causing short circuits, screens cracked from vibration on carts, and devices overheated near heat treatment areas, resulting in $45,000 in replacement costs and 300+ hours of production downtime annually.

Why Consumer Tablets Fail on the Factory Floor

Why Consumer Tablets Fail on the Factory Floor

| Failure Point | Consumer Tablet Limitation | Manufacturing Impact |

|---|---|---|

| Screen Durability | Standard glass (not strengthened), flush design | Cracks from minor drops, unreadable with scratches |

| Ingress Protection | No IP rating, exposed ports, minimal sealing | Dust/liquid damage, corrosion, electrical shorts |

| Temperature Range | 0°C to 35°C (32°F to 95°F) operating range | Shutdowns in hot/cold areas, thermal throttling |

| Battery Performance | Designed for intermittent use, limited cycles | Insufficient for full shifts, swells with constant charging |

| Touchscreen Operation | Requires bare fingers, precise touch | Unresponsive with work gloves, inaccurate with contaminants |

| Device Management | Limited enterprise features, consumer-focused | Difficult to secure, update, or monitor at scale |

The True Cost of Consumer Tablets in Manufacturing

Beyond device replacement costs, consumer tablets create hidden expenses:

Production Downtime: $500-$2,000 per hour in lost output

IT Support Time: 4-6 hours monthly per device for troubleshooting

Data Loss: Inventory counts, quality records, work orders

Safety Risks: Glass shards in production areas, electrical hazards

Workflow Disruption: Operators waiting for device replacements

What Is a Rugged Tablet for Manufacturing?

Unlike consumer devices, rugged tablets for manufacturing are engineered specifically for industrial environments with features that address the unique challenges of factory floors.

Design & Construction

Reinforced magnesium or polycarbonate chassis

Chemically strengthened Gorilla Glass or similar

Raised bezels to protect screen from direct impacts

Sealed ports with protective covers

MIL-STD-810G certification for shock/vibration

Environmental Protection

IP65-IP68 ratings (dust-tight, water-resistant)

-20°C to 60°C operating temperature range

Resistance to oils, chemicals, and solvents

Humidity tolerance: 5% to 95% non-condensing

UV resistance for outdoor areas

Industrial-Grade Components

Display Features

High brightness (800-1000+ nits)

Sunlight readable

Glove-friendly touch

Anti-reflective coating

Connectivity

Industrial-grade Wi-Fi

Bluetooth for peripherals

Optional 4G/5G cellular

Barcode/RFID options

Power & Battery

Hot-swappable batteries

12-18 hour shift life

Docking station support

Rapid charging

Key Benefits of Rugged Tablets in Manufacturing Operations

Increased Productivity

Zero Downtime: Work continues uninterrupted in challenging conditions

Faster Data Entry: Glove-friendly touch and barcode scanning

Real-Time Updates: Immediate access to inventory, work orders, quality data

Reduced Training: Consistent devices mean less retraining on replacements

Lower Total Cost of Ownership

5-7 Year Lifespan: Versus 12-24 months for consumer devices

Reduced Replacements: 80-90% lower failure rate in industrial settings

Minimal Maintenance: Sealed design requires less cleaning and care

Higher Resale Value: Retain 40-50% value after 3 years of use

Improved Data Accuracy

Real-Time Capture: Data entered at point of activity

Reduced Errors: Barcode/RFID scanning eliminates manual entry mistakes

Complete Records: No data loss from device failures

Audit Compliance: Tamper-evident logs and secure data storage

Enhanced Safety & Security

Worker Safety: No glass shards, sealed against contaminants

Data Security: Enterprise-grade encryption and access controls

Regulatory Compliance: Meets industry-specific requirements

Asset Protection: Theft-resistant designs and tracking capabilities

Case Study: Pharmaceutical Manufacturer

A pharmaceutical company replaced consumer tablets with rugged tablets in their cleanroom and packaging areas. Results after 2 years: 92% reduction in device failures, 40% faster batch record completion, and full compliance with FDA 21 CFR Part 11 electronic records requirements. The rugged tablets for manufacturing solution paid for itself in 14 months through reduced IT costs and improved operational efficiency.

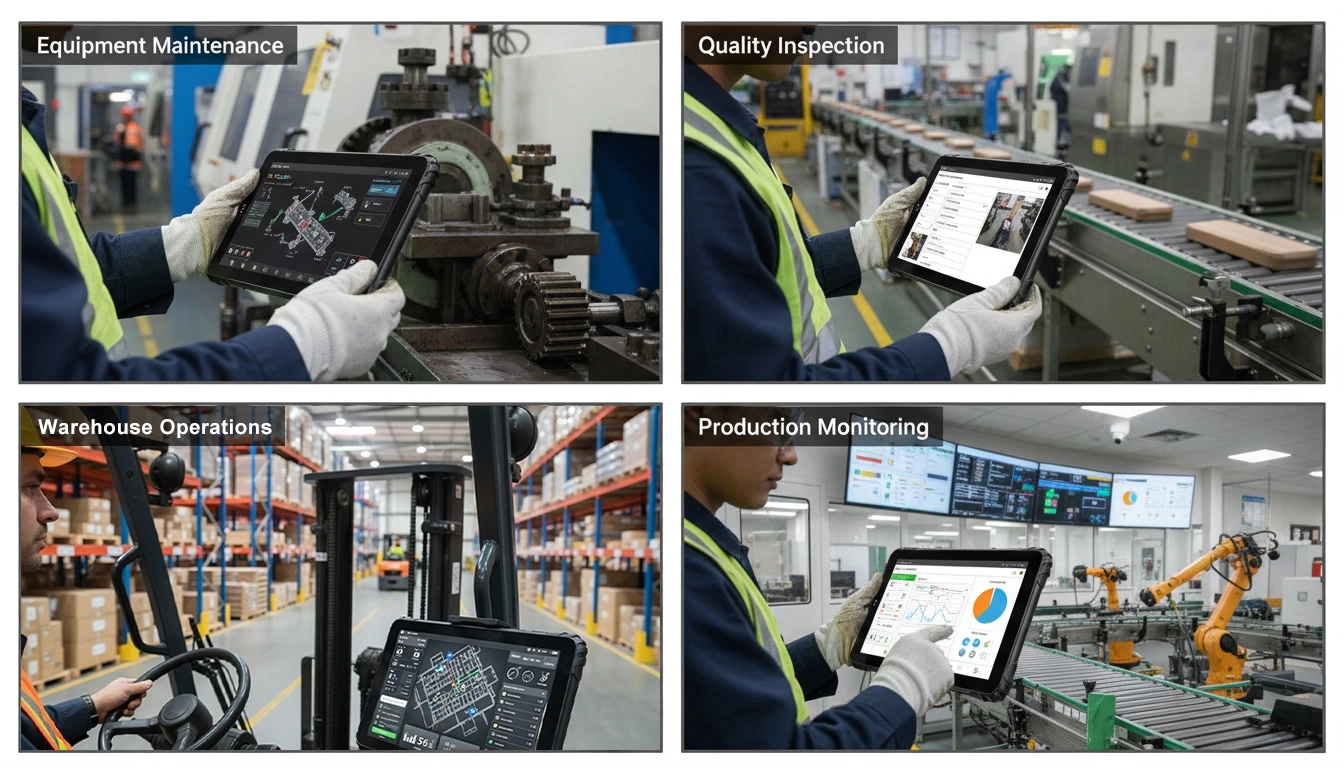

Typical Manufacturing Use Cases

Production Floor

Work instruction access

Quality inspection recording

Machine monitoring interfaces

Production count tracking

Andon system triggers

Warehouse & Logistics

Inventory management

Receiving/shipping verification

Pick/pack operations

Cycle counting

Forklift mounting

Maintenance & Repair

Preventive maintenance schedules

Repair work orders

Parts inventory lookup

Equipment manuals access

Technician time tracking

Quality Control

Inspection data collection

Non-conformance reporting

Statistical process control

Supplier material verification

Document control access

Assembly Lines

Assembly instructions

Component verification

Torque value confirmation

Serial number tracking

Line balancing support

Cleanrooms & Labs

Batch record management

Environmental monitoring

Compliance documentation

Sterile process tracking

Cleanroom-compatible designs

How to Choose the Right Rugged Tablet for Manufacturing

Step 1: Assess Your Environment

Physical Hazards

Drop heights expected?

Vibration levels?

Impact risks?

Compression forces?

Environmental Factors

Temperature ranges?

Dust/debris levels?

Liquid exposure?

Chemical contact?

Operational Needs

Shift durations?

Glove requirements?

Mounting needs?

Peripheral devices?

Step 2: Define Technical Requirements

Essential Certifications

MIL-STD-810G

IP65 or higher

Drop spec: 4-6 feet

Temperature range

Display Specifications

Size: 8-10 inches

Brightness: 800+ nits

Glove touch support

Sunlight readable

Connectivity & Peripherals

Barcode/RFID options

Wi-Fi performance

Cellular capability

Bluetooth peripherals

Step 3: Evaluate Total Cost of Ownership

| Cost Component | Consumer Tablet (3 years) | Rugged Tablet (5 years) |

|---|---|---|

| Device Purchase | $600 × 2.5 replacements = $1,500 | $1,800 × 1 = $1,800 |

| IT Support/Maintenance | $1,200 per device | $400 per device |

| Downtime Costs | $3,500 estimated | $500 estimated |

| Accessories/Protection | $300 (cases, screen protectors) | $200 (docks, mounts) |

| Total Cost | $6,500 | $2,900 |

| Cost per Year | $2,167/year | $580/year |

Step 4: Test Before Full Deployment

Always conduct a pilot program before large-scale implementation:

Test in your actual environment for 30-60 days

Evaluate with real operators performing normal tasks

Assess battery life across full shifts

Test connectivity in different facility areas

Verify compatibility with existing software systems

Evaluate vendor support responsiveness

Conclusion: The Right Tool for the Job

Manufacturing environments demand specialized tools designed for specific challenges. Just as you wouldn't use office chairs on a production floor or consumer-grade tools for precision assembly, mobile computing devices must match their operational environment.

Rugged tablets provide the durability, reliability, and performance that manufacturing operations require. While the initial investment may be higher than consumer devices, the long-term benefits—reduced downtime, improved data accuracy, lower total cost of ownership, and enhanced safety—make them the intelligent choice for forward-thinking manufacturers.

When evaluating rugged tablets for manufacturing, focus on matching device capabilities to your specific environmental challenges and operational requirements. The right rugged tablet isn't just a durable device—it's a productivity tool that empowers your workforce, protects your data, and supports your manufacturing excellence goals for years to come.