Tablet Manufacturer: OEM & ODM Tablet Manufacturing Explained

The tablet manufacturing landscape encompasses diverse capabilities ranging from mass-market consumer production to specialized industrial device development. Understanding the distinctions between different types of manufacturers, their processes, and capabilities is essential for businesses seeking to develop or source tablet solutions aligned with specific operational requirements and market objectives.

What Is a Tablet Manufacturer?

A tablet manufacturer is an organization that designs, develops, and produces tablet computing devices. Manufacturers vary significantly in their focus, capabilities, and business models, with some specializing in high-volume consumer electronics while others concentrate on industrial or specialized applications. For example, manufacturers in the latter category often focus on producing a specialized rugged tablet, engineered to meet demands for rugged construction, extended temperature operation, or specific industry certifications such as IP67 and MIL-STD-810H.

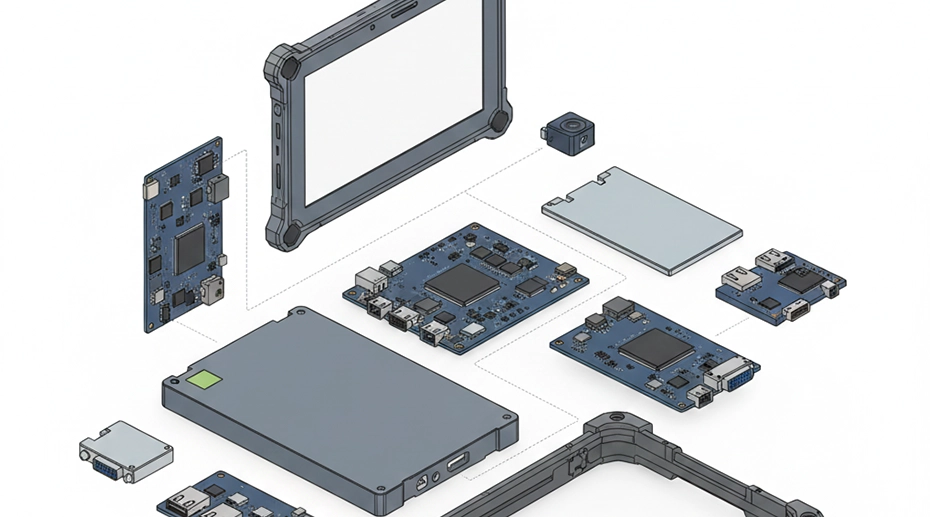

A tablet manufacturer is an organization that designs, develops, and produces tablet computing devices. Manufacturers vary significantly in their focus, capabilities, and business models, with some specializing in high-volume consumer electronics while others concentrate on industrial or specialized applications. For example, manufacturers in the latter category often focus on producing a specialized rugged tablet, engineered to meet demands for rugged construction, extended temperature operation, or specific industry certifications such as IP67 and MIL-STD-810H.The manufacturing scope typically includes hardware design, component sourcing, PCB assembly, system integration, software implementation, quality testing, and regulatory compliance. Manufacturers may operate their own production facilities or manage production through partnered manufacturing networks, with capabilities scaling from prototype quantities to mass production volumes.

Types of Tablet Manufacturers: Consumer vs Industrial

Consumer Tablet Manufacturer

Focus: Mass-market consumer electronics with emphasis on aesthetics, multimedia, and entertainment features

Volume: High-volume production (thousands to millions of units)

Lifecycle: Short product cycles (6-18 months) with frequent model updates

Durability: Standard consumer-grade construction with limited environmental protection

Target Market: Retail consumers, educational institutions, general business users

Industrial Tablet Manufacturer

Focus: Specialized devices for demanding environments with emphasis on reliability and longevity

Volume: Medium to low volume production with customization options

Lifecycle: Extended product support (3-7+ years) with stable hardware platforms

Durability: Rugged construction with IP ratings, MIL-STD certifications, and extended temperature operation

Target Market: Industrial automation, logistics, field service, transportation, utilities

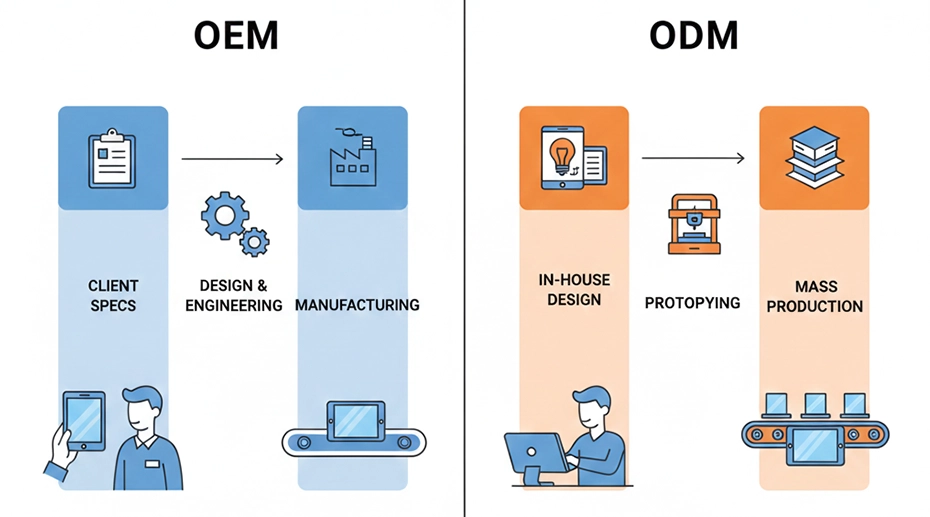

OEM vs ODM Tablet Manufacturing: What's the Difference?

| Aspect | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Ownership | Client provides specifications and design; manufacturer produces to client specifications | Manufacturer provides both design and production; client brands the finished product |

| Development Control | Client controls design, specifications, and intellectual property | Manufacturer controls design with client input on branding and feature selection |

| Time to Market | Longer development cycles due to custom design and validation | Shorter timelines by utilizing existing platforms and designs |

| Cost Structure | Higher initial investment in design and tooling | Lower initial costs through shared platform development |

| Flexibility | High customization potential for unique requirements | Limited to manufacturer's existing platform capabilities |

| Ideal For | Companies with specific technical requirements and design resources | Companies seeking branded solutions without extensive design investment |

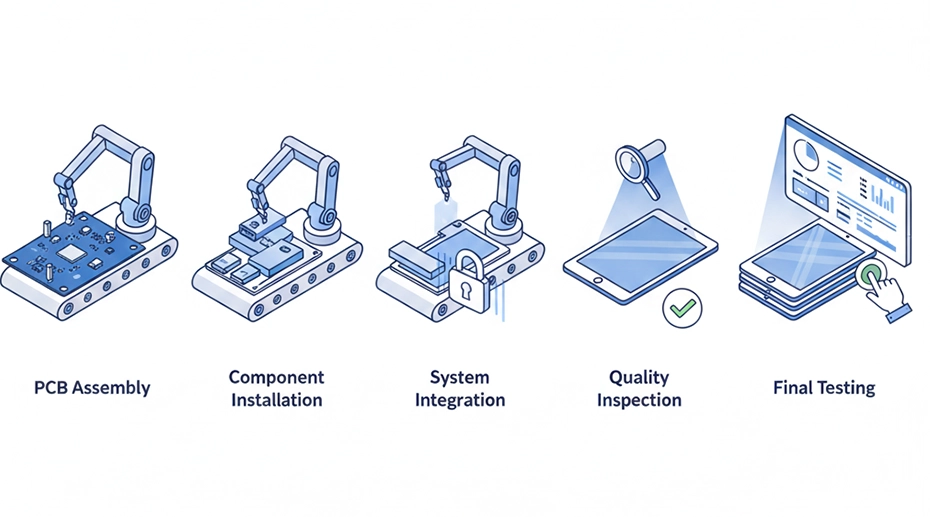

Tablet Manufacturing Process Overview

Design & Engineering Phase

Initial requirements analysis, conceptual design, mechanical engineering (enclosure, mounting, thermal), electrical design (PCB layout, component selection), and industrial design for user interface and ergonomics.

Structural Development

Prototype development, tooling creation for plastic/metal components, material selection for durability requirements, and validation of mechanical integrity under expected environmental conditions.

Motherboard & Component Integration

PCB fabrication and assembly (SMT process), component sourcing and qualification, system integration of processor, memory, storage, and peripheral interfaces with rigorous electrical testing.

System & Software Implementation

Operating system integration, driver development, firmware programming, application framework implementation, and compatibility testing with target software ecosystems.

Testing & Quality Assurance

Environmental testing (temperature, humidity, shock, vibration), functional testing, battery life validation, display quality assessment, and reliability testing under simulated operational conditions.

Certification & Compliance

Regulatory certification (FCC, CE, RoHS), industry standards compliance (IP ratings, MIL-STD), wireless certifications (cellular, Wi-Fi, Bluetooth), and industry-specific certifications as required.

Key Capabilities to Look for in a Tablet Manufacturer

Customization & Design Flexibility

Ability to modify hardware specifications, enclosure design, I/O configurations, and branding elements to meet specific application requirements rather than offering only standard configurations.

System & Software Support

Comprehensive software development capabilities including OS customization, driver development, application framework support, and compatibility with enterprise management systems.

Certification & Compliance Expertise

Established processes for achieving and maintaining necessary certifications including environmental ratings (IP, MIL-STD), regulatory approvals, and industry-specific compliance requirements.

Production Capacity & Scalability

Appropriate manufacturing infrastructure to support required production volumes, with flexibility to scale production up or down based on demand fluctuations and project timelines.

Product Lifecycle Management

Commitment to long-term product availability, component sourcing stability, and continued support throughout the expected operational lifespan of industrial deployments.

Quality Assurance & Testing

Comprehensive testing protocols covering environmental stress, functional validation, reliability assessment, and continuous quality monitoring throughout the production process.

Industries Served by Industrial Tablet Manufacturers

Logistics & Warehouse Management

Rugged tablets for inventory management, order picking, shipping verification, and forklift-mounted operations requiring durability, scanning capabilities, and real-time data synchronization.

Manufacturing & Industrial Automation

Factory floor tablets for production monitoring, quality control, equipment maintenance, and process documentation in environments with vibration, dust, and temperature variations.

Vehicle & Transportation Systems

In-vehicle computing platforms for fleet management, navigation, ELD compliance, and driver information systems with vehicle integration and environmental durability.

Utilities & Field Service Operations

Field-deployable tablets for infrastructure inspection, maintenance reporting, asset management, and remote workforce coordination in outdoor and challenging environmental conditions.

How to Choose the Right Tablet Manufacturer for Your Business

Define Your Technical Requirements

Clearly articulate environmental specifications (temperature, moisture, shock/vibration), performance requirements, connectivity needs, and industry compliance standards before evaluating potential manufacturing partners.

Evaluate Manufacturing Expertise

Assess the manufacturer's experience with similar projects, technical capabilities in relevant areas (rugged design, specific certifications), and depth of engineering resources available for your project.

Consider Volume & Scalability

Match your production volume requirements (prototype, pilot, mass production) with the manufacturer's capacity and flexibility to scale production according to your growth projections and timeline.

Review Quality & Testing Processes

Examine the manufacturer's quality management system, testing protocols, defect rates, and approach to continuous improvement to ensure product reliability aligns with your expectations.

Assess Long-Term Support

Evaluate the manufacturer's commitment to product lifecycle management, component availability guarantees, and ongoing technical support throughout your deployment period.

Verify Communication & Project Management

Ensure clear communication channels, transparent project management processes, and cultural compatibility to facilitate smooth collaboration throughout the development and production phases.

From Tablet Manufacturer to Rugged Tablet Solutions

Looking for a rugged tablet manufacturer for industrial applications? Industrial tablet manufacturing requires specialized expertise in durable design, environmental testing, and long-term product support. Manufacturers focusing on industrial applications combine hardware engineering with a deep understanding of operational challenges in demanding environments. They are adept at delivering end-to-end rugged tablet solutions that are purpose-built to withstand harsh conditions, ensuring reliability where conventional devices would fail.

The transition from general tablet manufacturing to industrial solutions involves additional considerations including extended temperature components, robust mechanical design, comprehensive environmental testing, and industry-specific certification processes. Manufacturers with an industrial focus typically offer greater customization flexibility, longer product lifecycles, and deeper technical collaboration throughout the development process. This collaborative approach is key to developing integrated rugged tablet solutions that encompass not only the hardware but also software optimization, accessory ecosystems, and lifecycle support tailored to specific industrial workflows.

For organizations seeking industrial-grade tablet solutions, understanding manufacturing capabilities and processes provides a foundation for effective partner selection and project planning.

Explore Our Rugged Tablet Manufacturing Capabilities