RFID Tablet Solutions for Industrial Asset Tracking and Fleet Operations

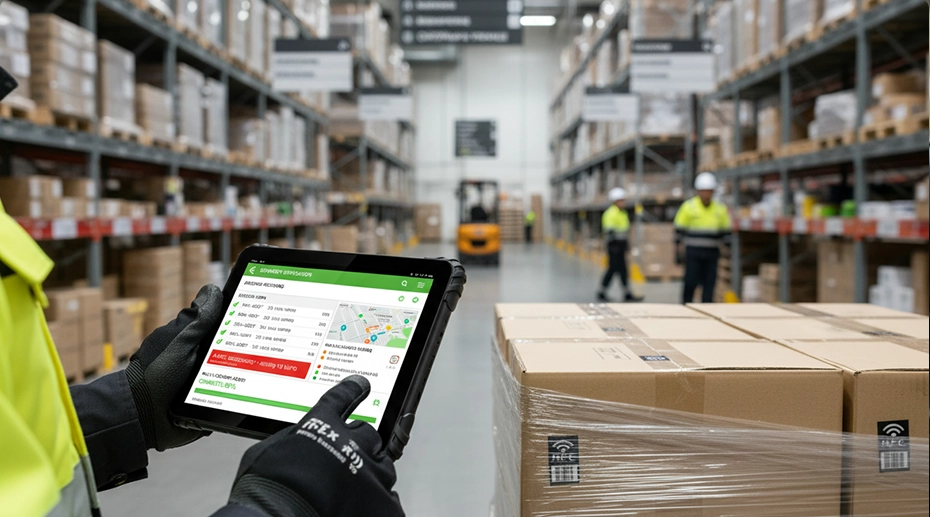

Industrial operations require reliable tools for asset identification and data capture that can withstand demanding environments while maintaining connectivity. Rugged RFID tablets serve as critical hardware components in these workflows, providing the durable computing platform necessary for real-time asset tracking across manufacturing, field service, and fleet operations without requiring complete system overhauls.

Industrial operations require reliable tools for asset identification and data capture that can withstand demanding environments while maintaining connectivity. Rugged RFID tablets serve as critical hardware components in these workflows, providing the durable computing platform necessary for real-time asset tracking across manufacturing, field service, and fleet operations without requiring complete system overhauls.

What Is an RFID Tablet in Industrial Applications?

Definition of an Industrial RFID Tablet

An industrial RFID tablet is a rugged Android computing device with an integrated UHF or HF RFID reader. Unlike consumer tablets or standalone scanners, this hardware combines mobile computing capabilities with automatic identification technology in a single, durable terminal designed specifically for industrial environments where reliability and environmental resistance are paramount.

How RFID Tablets Enable Asset Identification and Data Capture

The integrated RFID reader transforms the tablet into an active identification tool capable of reading passive RFID tags without direct line-of-sight. This enables workers to capture asset data—such as item identification, location, and status—directly into the device's applications, creating digital records without manual data entry or separate scanning equipment.

Why RFID Tablets Are Ideal for Industrial Asset Tracking

Real-Time Asset Visibility Across Industrial Environments

Rugged RFID tablets maintain functionality across diverse industrial settings including factory floors, outdoor yards, warehouse facilities, and remote field locations. This hardware durability ensures asset tracking continues where traditional computing devices would fail, providing consistent visibility regardless of environmental conditions.

Reduced Manual Scanning and Improved Data Accuracy

By automating the identification process, RFID tablets eliminate the need for manual barcode scanning and paper-based tracking. This reduces human error in data capture, improves inventory accuracy to 99% or higher, and allows workers to focus on operational tasks rather than administrative documentation.

Mobility and Durability for Field Operations

Industrial-grade construction with IP67 sealing, MIL-STD-810H certification for shock and vibration resistance, and extended temperature range operation (-20°C to 60°C) ensure RFID tablets function reliably during mobile field operations where consumer devices would be impractical or unsafe to use.

Typical Industrial and Fleet Use Cases for RFID Tablets

Asset Tracking in Manufacturing and Industrial Facilities

In manufacturing environments, RFID tablets track tools, containers, production equipment, and work-in-progress items. Maintenance teams use them to locate specialized equipment, verify calibration status, and manage preventive maintenance schedules across large facilities with thousands of tagged assets.

Fleet Asset Identification and Equipment Monitoring

Vehicle-mounted RFID tablets enable drivers and operators to verify loaded equipment, track cargo, and monitor specialized fleet assets. These devices provide the hardware platform for in-cab verification systems that work alongside existing fleet management solutions without replacing them.

Field Service and Outdoor Asset Operations

Construction, utility, and energy sector operations use RFID tablets to track equipment, materials, and tools across dispersed job sites. The devices withstand outdoor conditions while providing accurate asset counts and location data for project management and resource allocation.

RFID Tablet Deployment Scenarios

Handheld RFID Scanning for Mobile Operations

Portable RFID tablets enable workers to move freely through facilities while conducting inventory audits, asset verification, and quality checks. The integrated handle or grip design allows for comfortable extended use during shift-long scanning operations.

Vehicle-Mounted RFID Tablets for Fleet Workflows

Secure docking stations and vehicle cradles enable RFID tablets to function as fixed in-cab terminals. These mounted configurations provide continuous power, optimized antenna positioning, and protection against vehicle vibration while allowing for quick removal when needed.

Fixed-Point or Semi-Fixed RFID Data Collection

Wall-mounted or stand-configured RFID tablets serve as stationary data collection points at receiving docks, tool crib entrances, or quality check stations. These semi-fixed deployments provide consistent scanning performance for high-traffic asset movement points.

System Compatibility and Software Integration Readiness

Compatibility with Asset Tracking and Enterprise Systems

Industrial RFID tablets are designed to be compatible with existing asset tracking software, Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP) platforms. Standard communication protocols and data formats enable integration with customer or third-party backend systems for data synchronization and workflow coordination.

API and SDK Support for Custom Applications

Comprehensive API documentation and Software Development Kits (SDKs) provide hardware enablement for custom application development. System integrators and software developers can access RFID reader controls, device functions, and sensor data to build tailored solutions that match specific operational workflows.

Device Management and Connectivity Options

Enterprise-ready connectivity includes 4G/5G cellular, dual-band Wi-Fi, Bluetooth 5.x, and GPS/GNSS positioning. Support for Mobile Device Management (MDM) platforms enables remote configuration, security enforcement, and software updates across distributed device fleets.

Key Hardware Features to Look for in an RFID Tablet

RFID Reader Performance and Antenna Design

Effective RFID tablets feature optimized antenna designs and reader sensitivity appropriate for the operational environment. UHF configurations typically offer longer read ranges (3-8 meters) for warehouse applications, while HF options provide reliable short-range performance for item-level tracking.

Rugged Design for Industrial Conditions

Essential rugged specifications include IP65/67 ratings for dust and water resistance, MIL-STD-810H certification for shock and vibration tolerance, and extended temperature operation ranges. Magnesium alloy or reinforced polymer construction provides structural integrity without excessive weight.

Battery Life and Continuous Operation Support

Industrial RFID tablets should support full-shift operation (8-12 hours) with standard batteries and offer hot-swappable battery options for continuous workflows. Intelligent power management and vehicle docking with ignition sensing ensure reliable operation during mobile use.

How to Choose the Right RFID Tablet Solution for Your Operations

Match RFID Capabilities to Asset Types and Environment

Select RFID tablet specifications based on the materials being tracked (metal, liquid, or standard items), required read distances, and environmental interference factors. Consider whether UHF or HF technology better matches the asset density and scanning scenarios in your operations.

Consider Mounting and Mobility Requirements

Determine whether handheld, vehicle-mounted, or semi-fixed deployment best supports your workflows. Evaluate docking compatibility, mounting accessories, and ergonomic design based on how the device will be used during daily operations.

Ensure Long-Term Hardware Reliability and Support

Look for industrial-grade construction backed by appropriate warranties and lifecycle commitments. Consider the manufacturer's track record with similar deployments, availability of spare parts, and support for future software and security updates throughout the expected operational lifespan.

Rugged RFID Tablet Solutions from TOPICON

Industrial RFID Tablet Platforms for Asset Tracking Applications

TOPICON provides rugged RFID tablet hardware platforms specifically engineered for industrial asset tracking applications. These devices combine Android computing, integrated RFID technology, and industrial durability to serve as reliable data capture terminals within customer-managed tracking systems. For detailed specifications and configuration options, explore our rugged RFID tablet solution portfolio or contact our technical team to discuss industrial RFID tablet hardware platform requirements.

Frequently Asked Questions About RFID Tablets

Is an RFID tablet a complete asset tracking system?

No, an RFID tablet is not a complete asset tracking system. It is a hardware device that serves as a data capture and computing terminal within a larger asset tracking ecosystem. The tablet provides the interface for scanning RFID tags and running applications, while the complete tracking system includes backend software, database infrastructure, and business logic typically managed by the customer or a specialized software provider.

Can RFID tablets work with existing enterprise systems?

Yes, industrial RFID tablets are designed to integrate with existing enterprise systems through standard communication protocols and APIs. They can transmit captured data to Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) platforms, and custom databases, functioning as hardware endpoints within established IT architectures.

What is the typical lifespan of an industrial RFID tablet?

Properly specified industrial RFID tablets typically have an operational lifespan of 5-7 years in continuous industrial use. This extended lifecycle is achieved through rugged construction, industrial-grade components, and manufacturer support for software updates and security patches throughout the deployment period.

Summary: Industrial RFID tablets serve as durable, mobile computing platforms for asset identification and data capture across manufacturing, logistics, and field operations. These hardware devices enable real-time tracking, reduce manual processes, and integrate with existing enterprise systems while withstanding demanding environmental conditions. When evaluating options, focus on RFID performance matching your asset types, rugged specifications appropriate for your operating environment, and long-term reliability for sustained operational value.